When it comes to guitar sound network, we tend to think of PP, PVC and papyrus material, and PP and PVC are the same plastic material, so how to distinguish between these two materials, the two do not use the material in the application of what is the difference, let me take you together to understand the following.

PP is the abbreviation of polypropylene, PP is an environmentally friendly material, is a thermoplastic resin made from the polymerization of propylene, has excellent physical, mechanical and chemical properties. PVC material that is polyvinyl chloride, it is one of the world’s largest production of plastic products. the difference between PP and PVC can be clearly distinguished from the appearance and feel.

The ways to distinguish between PP and PVC

1. Specific gravity

PP is lighter than mineral water, while the specific gravity of PVC is two times that of PP.

2. Burning

PP smells like candles melting when it burns, while PVC burns with a big and pungent smell.

3. Feel

PP is hard to the touch, while PVC is relatively soft.

4. Thermal expansion and contraction

PP will have obvious thermal expansion and contraction phenomenon when burning, while PVC does not.

5. Tensile strength

the same thickness and hardness of PP and PVC, PP’ s tensile strength is relatively large.

6. Sound

the same thickness and hardness of PP and PVC materials, when cut with scissors, PP material sound is crisp, while the sound of PVC material is relatively muffled.

7. Gloss

poor gloss of PP, PVC gloss is relatively good.

8. Heat dissipation

PP heat dissipation is slower than PVC, and thermal conductivity is not as good as PVC.

9. Spark

When it with a lighter, after leaving the open flame, PP will continue to burn, while PVC burns quickly and has the phenomenon of dripping oil.

The different application of PP and PVC

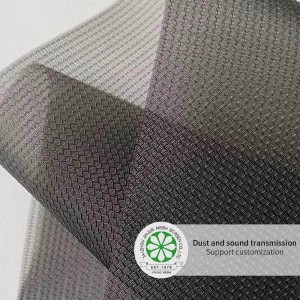

PP and PVC are used differently in audio mesh. PP is generally used for dustproof mesh and PVC is generally used for audio speaker mesh. This is because PP has better hardness and rigidity, and has high surface free energy and stable chemistry, so it is suitable for dustproof netting. PVC is relatively soft, less hard and rigid, and has poor heat resistance, but most of the speaker nets in the market are made of PVC.

In addition to the above uses, PP and PVC have other uses in sound nets, such as PP can be used as insulation pipes and boards, while PVC can be used as dustproof nets, threshold protection strips and board thickness controllers, etc.

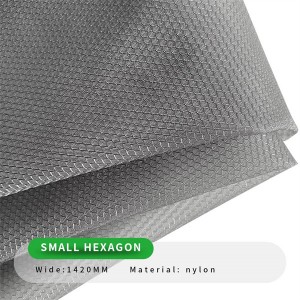

Taizhou Jinjue Mesh Screen Co., Ltd. is a production and processing factory specializing in speaker mesh hot pressing processing, speaker wrap cloth, weft knitting mesh processing. The company has professional technical personnel to cooperate with you in the development and design of hot pressed fabric technology.

The company has 2500 square meters of production workshop, there are more than 500 kinds of colors of speaker mesh for customers to choose, also can be provided by customers to sample to sample, custom-made, and fast delivery! With its excellent quality, reasonable price and many domestic speaker factory, audio equipment factory, mesh processing factory to become a friendly partner. Quality assurance, reasonable price, timely delivery, satisfactory service. Welcome new and old customers to call and consult.

英文版主图6-300x300.jpg)