Introduction

Nylon mesh fabric is a versatile and widely used material in various industries due to its unique characteristics. This article aims to introduce the concept and classification of nylon mesh fabric, highlight its features, applications, production process, cleaning and maintenance, as well as its future trends and prospects.

Concept and Classification of Nylon Mesh Fabric

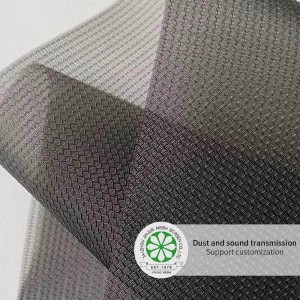

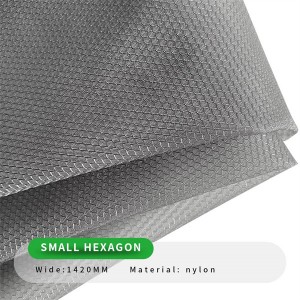

Nylon mesh fabric is a type of synthetic textile made from nylon fibers that are woven or knitted into a mesh-like structure. It is commonly used in sportswear, footwear, protective gear, and fashion accessories due to its lightweight, breathable, and durable properties.

There are several types of nylon mesh fabrics, including monofilament, multifilament, and braided mesh. Monofilament mesh has a single nylon filament per weave, providing excellent strength and durability. Multifilament mesh has multiple nylon filaments per weave, resulting in a more open and breathable structure. Braided mesh is made by intertwining multiple strands of nylon fibers, creating a strong and flexible mesh.

Importance of Nylon Mesh Fabric in Various Industries

Nylon mesh fabric plays a crucial role in various industries due to its unique characteristics. Its excellent elasticity allows it to stretch and return to its original shape without losing its strength or durability. This feature makes it ideal for use in sportswear, such as running shoes and tennis shoes, where comfort and support are essential.

In addition to its athletic applications, nylon mesh fabric is also commonly used in fashion and accessories. Its lightweight and breathable properties make it an ideal choice for clothing items like jackets, pants, and shirts. It is also used as a lining material for bags and other accessories to provide ventilation and reduce weight.

One of the significant advantages of nylon mesh fabric is its ability to allow moisture to escape from the body. This property makes it ideal for use in footwear, especially in specialized running shoes. The mesh design allows air to circulate through the shoe, keeping the feet dry and cool during physical activity.

To maintain the cleanliness of nylon mesh fabric shoes, it is important to follow specific cleaning procedures. For small particles like sand, it is recommended to tap the sole of the shoe gently to dislodge the sand before cleaning. For dust or dirt, soaking the shoes in water for half an hour can help loosen the debris before washing them according to standard cleaning methods.

Applications of Nylon Mesh Fabric

Nylon mesh fabric finds its application in various fields due to its unique properties. One of the primary areas of application is in professional sportswear, such as running shoes and tennis shoes. The lightweight and breathable nature of nylon mesh fabric provides comfort and support during physical activity.

Apart from athletic wear, nylon mesh fabric is also popular in fashion due to its stylish appearance and comfortable feel. It is often used in clothing items like jackets, pants, and shirts to provide ventilation and reduce weight. Additionally, it is used as a lining material for bags and other accessories to enhance their functionality and aesthetic appeal.

Production Process and Cleaning Maintenance of Nylon Mesh Fabric

The production process of nylon mesh fabric involves selecting appropriate materials, such as high-quality nylon fibers, and using advanced weaving or knitting techniques. The key challenge in producing nylon mesh fabric lies in ensuring consistent quality and meeting specific requirements for different applications. Quality control measures are implemented throughout the production process to ensure that the final product meets industry standards.

Cleaning and maintenance of nylon mesh fabric require specific care to preserve its durability and appearance. It is important to follow the manufacturer’s instructions for cleaning the fabric to avoid damaging it. For general cleaning purposes, mild detergent mixed with water can be used to remove dirt and stains. However, harsh chemicals or excessive scrubbing should be avoided as they can damage the fabric’s fibers.

Future Trends and Prospects of Nylon Mesh Fabric

The demand for nylon mesh fabric is expected to continue growing in the future due to its versatile applications and unique properties. Advancements in technology and innovation will play a significant role in shaping the future of this industry. New materials and manufacturing techniques will further enhance the performance and durability of nylon mesh fabric products.

In terms of market trends, there is a growing demand for sustainable and eco-friendly alternatives to traditional materials. As consumers become more environmentally conscious, manufacturers are exploring ways to produce nylon mesh fabric using recycled materials or alternative fibers. This trend is expected to drive innovation in the industry and create new opportunities for growth.

Looking ahead, China’s nylon mesh fabric industry faces both challenges and opportunities. With a large domestic market and increasing global demand, China has the potential to become a major player in this industry. However, competition from established players in developed countries remains intense. To succeed in this competitive market, Chinese manufacturers need to focus on improving product quality, adopting advanced technologies, and developing innovative solutions that meet changing consumer demands.

Conclusion

Nylon mesh fabric is a versatile material with numerous applications across various industries due to its unique characteristics. Its excellent elasticity, breathability, and moisture-wicking properties make it ideal for use in sportswear, fashion accessories, and footwear. The production process requires careful selection of materials and advanced weaving or knitting techniques to ensure consistent quality. Proper cleaning and maintenance are essential to preserve the durability and appearance of nylon mesh fabric products.

Looking forward, the future of nylon mesh fabric is promising due to growing demand and advancements in technology. Sustainability is becoming an increasingly important factor in consumer preferences, driving innovation in the industry towards eco-friendly alternatives. China’s nylon mesh fabric industry has both challenges and opportunities ahead, requiring continuous improvement in product quality, adoption of advanced technologies, and development of innovative solutions to remain competitive in the global market.

英文版主图6-300x300.jpg)